Palletizing Extra Tall Pallets

Client & Objective

A leading manufacturer of molded fiber egg cartons turned to MMCI to design a highly automated robotic cell capable of stacking various bundles on extra tall pallets.

The Challenges

Our primary objectives were to improve productivity and reduce the amount of downtime that our client was experiencing in their current operation. However, other challenges included:

- Palletizing four separate outfeed stations with one robotic arm

- Developing a method for creating pallets that extended to heights of up to 10 feet tall

- Prepping various-sized bundles for pick up and placement

The Solution

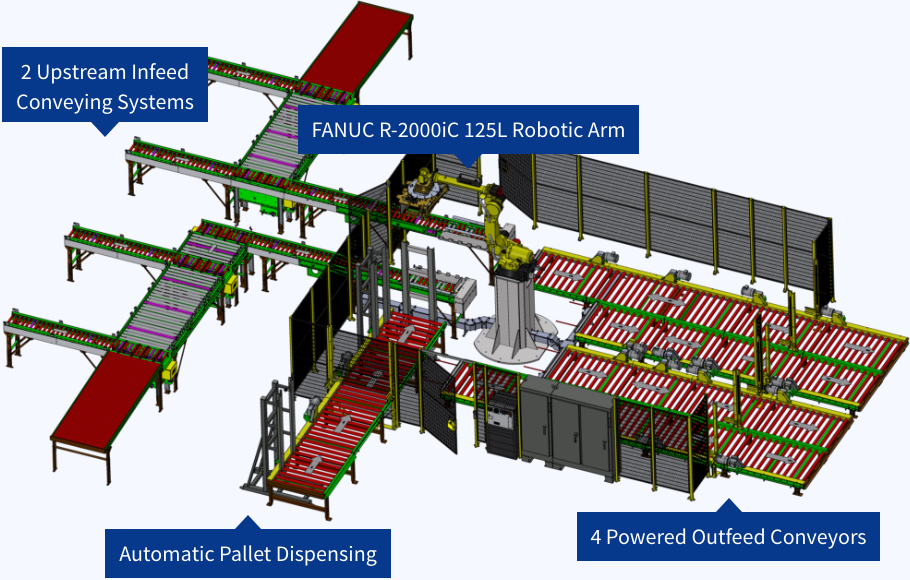

To address this challenge, our engineers specified a FANUC R-2000iC 125L robotic arm for its 10 foot plus reach and 275-pound payload capacity. The robotic arm was mounted on an extra tall base in the center of the cell to capitalize on its full range of motion.

Upstream Automation

To increase productivity, we developed an infeed conveying system that prepared the bundles for pickup by the robot and outfitted the robotic arm with customized end-of-arm tooling capable of picking and placing multiple bundles at one time.

Automated Pallet Dispensing

Further productivity gains were achieved by integrating an automated pallet hopper into the cell and outfitting the end-of-arm-tooling with forks that adjust and grip each pallet from the center to ensure accurate pallet placement every time.

Downstream Automation

We then paired the palletizing robot with 4 powered outfeed conveyors that deliver the finished pallets to the end-of-line collection area.

Intelligent Cell Design

When finalizing the design, we moved the label printer (that was the most frequent cause of downtime) outside of the robotic cell so that operators could easily address issues without needing to stop the robot in the cell.

The Results

By designing more intelligent infeed and outfeed systems, utilizing a more versatile robotic arm, and designing more efficient end-of-arm-tooling, we were able to increase throughput, reduce downtime and set our client on a path to greater productivity.

How Can We Help?

At any stage of your automation project, we can help.

Call us at 314-438-3300 or fill out the form below.