Our Work

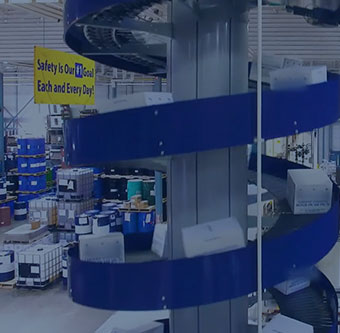

We are extremely proud of the fact that so many world-class companies trust our team with their material handling, and warehouse automation & order fulfillment processes.

Very Satisfied Customers

We work with many leading companies throughout the world across a variety of industries to deliver material handling solutions worthy of global leaders.

Over 1,000 Game Changing Solutions

Throughout the U.S.

When it's all said and done, we create Game Changing Solutions. Solutions that truly improve productivity, help you beat your competition and impact your bottom line.

How Can We Help?

At any stage of your automation project, we can help.

Call us at 314-438-3300 or fill out the form below.